Slab

THE ALUMINIUM PANEL SLAB FORMWORK THAT IS EASY TO HANDLE, REQUIRES MINIMUM MATERIALS, DELIVERS SHORT SHUTTERING TIMES AND EXCELLENT CONCRETE SURFACE

THE ALUMINIUM PANEL SLAB FORMWORK THAT IS EASY TO HANDLE, REQUIRES MINIMUM MATERIALS, DELIVERS SHORT SHUTTERING TIMES AND EXCELLENT CONCRETE SURFACE

HIGHLY EFFICIENT SYSTEM FOR SLAB FORMWORK

Aludeck formwork system is produced with robotic welding in Europe by PZ Scaffoldings Ltd. HIMSKAF SYSTEMS PVT. LTD. has exclusive representative rights for India & all neighboring countries for this system.

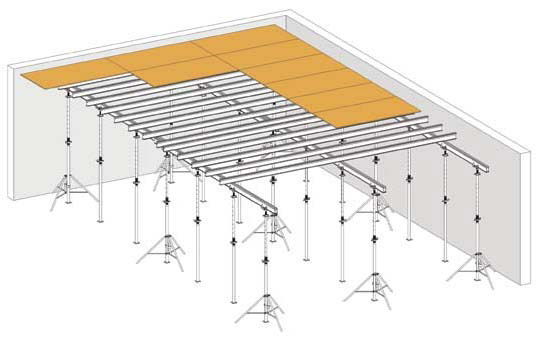

A simple modular slab decking system, RapiFlex enables fast and safe erection and dismantling while utilizing a small number of parts and deploying less labour. The light weight of the ALite Aluminum beams, or, S20 and S16 timber beams is an added advantage. The flexibility of the system makes it suitable for use thickness and geometry of the slab.

ALite Aluminum Formwork beams A150/ A120 and B150, as also, S20 and S16 timber formwork beams are all generally suitable for use both as primary and secondary runners. The ability to overlap them eliminates any need for cutting these to required length, thereby extending its life and avoiding any wastage of material.

RapiFlex Decking System is suitable for use under slabs of any thickness and configuration. This system can be designed for practically any required staging height of the slab, and is fully compatible for application with Props and any decking system with well defined load parameters

Our design team can assist in providing a most detailed, cost effective and safe decking solution for any project as per client's requirement.

The added advantage of using ALite light weight Aluminum formwork beams is that it can also be integrated with MultiPro‐XT System, suitable for wall concreting, as also, QFlex Column Formwork system, thereby, enabling a substantial reduction in inventory.

RapiDeck Slab Formwork System

System Advantages:RapiDeckAlite and RapiDeckPro systems deploy the technique of early striking to facilitate the removal of formwork in 3 to 4 days after concreting a slab, while supporting staging consisting of props or scaffold decking remains undisturbed under the concreted sloab for the required longer duration, until the concrete is strong enough to support its own weight over its full span.

Temporary Edge protection is used in construction work, primarily to prevent persons, or objects from falling from work surfaces like concrete slabs etc. These surfaces may be horizontal, or inclined. As per the European standard guidelines, Class A, Class B, and Class C classifications have been made for the type of protection required.

Class A is generally recommended for most concrete frames, formwork decks, stairways, flat roofs (up to 10 degree slopes),etc. HIMSKAF EDGEGUARD SYSTEM offers a higher standard of edge protection to reduce the risk of falls from heights generally following the above guidelines.

Many traditional methods of guardrail protection in the formwork, steelwork and slab edge applications no longer offer adequate edge protection when measured against the new safety guidance requirements for multi‐storeyed construction.

The HIMSKAF EDGEGUARD has been developed to provide a new standard of edge protection. It sets a better level of edge protection performance, and offers high visibility reassurance on site

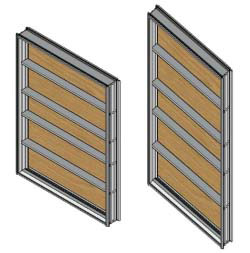

HIMSKAF EDGEGUARD has a number of important features and benefits:

Handling

Range of options